Design, Innovation,

Manufacturing Bass Cases

Tuff-Lite Cases are specially engineered with exact specifications. We

have developed a durable, lightweight case that is super protective and very

functional.

So many bass and cello cases presently offered around the world today are too

heavy, too big, too clumsy to use...or all the above. Most all cases were

originally designed by someone first taking some measurements of the basic case

they need and then mold a case with only a rough idea of how it might turn out.

Because of this (still), the cases tend to look angular: Sharp angles, long

stretches of the case having 'weak' spots and cases that while they may keep the

bass from getting crushed, the concussion inside the case, is just as damaging and

costly to the instrument.

Tuff-Lite cases are just that: Tuff and lightweight. Rather than

design our new cases as 'after thoughts', we work closely with an engineering

firm that is specialized in the aerospace industry and experienced in planning and

designing with hundreds of parameters, measurements, restrictions and

requirements. While we weren't actually making fighter jets, we used the

same smart people that designed them for our own cases. We dream, they

design, then we build. Simple right!? Well, it took a long

time and more than a few prototypes until we got the perfect case. As our

company employs bassists that work in our company, we know first hand what some

worries and concerns were as well as what ultimate goal of light, functional and

protective case.

Our Dream Case: Light, easy to use, well made, durable, strong

and protective.

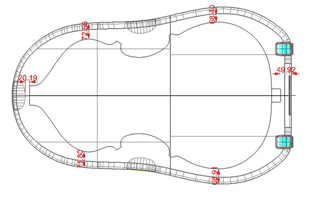

First, the most unexpected surprise was actually finding and hiring an

experienced engineering firm that could put our dream into reality. We actually scanned

basses that gave us the exact measurements all around the bass. This way, there

is no wasted space. Wasted space makes for extra, unneeded weight. We knew

exactly what the typical bass (size) would be and could design and plan

accordingly. What normal, everyday professional bass and cello players

take for granted, we looked at every nook and cranny of the case for economy of

weight and the ultimate protection. Every rivet and bolt has been

accounted for and factored in the overall weight and balance of the case.

Additionally, there were all sorts of accessories or facets inside the case

that would make the bass safer. We looked at everything!

Sizing. Again, we wanted a case that most of the world's basses would

fit. Most people travel with a 3/4 size bass. For our new Ultra

case, we decided on a typical, middle of the road ('Plain Jane') bass size:

3/4 bass with regular arching, normal string length of 41-42", the back around

43 or 44" etc... we measured several basses. The Thompson Plywood, Kay,

3/4 size Wilfer, etc... we scanned the exact bass into a 3 dimensional size of

the instrument, then designed our case around that size and shape of the bass.

As far as we know, this has never been done before to this degree. The Ultra

will fit 90% of the world's basses.

After we agreed on the right sized bass and general size of the case,

we then turned our attention to how to design a case that would best protect

it. When designing and researching a new case, we instructed our engineers

to plan for the worst treatment of that case. While they had never seen

the old Samsonite Gorilla commercials, we had to show them how

harsh some of the handlers could be. Not only did the case have to

be strong to protect, the design (of the inside) parts of the case were just as

important, if not more so. 'Concussive' damage to a bass is probably the most

prevalent way instruments are damaged by the airlines.

We used air bags years ago and while they looked 'smart' we felt that

they didn't do too much and gave a false sense of security. The air

wouldn't hold. Additionally we also tried special kinds of canopy shock

absorber designs that will allow the bass to bounce a little inside (ie to

minimize impact concussion type damage.) We literally tried everything

so that in the end, we'd have the safest, best case offered in the world.

The 'bouncy' idea too, we didn't like for various reasons. The only way to

truly find which was was best, is to build it first, then throw the case, drop

and slam it.....with the bass inside! We have found that our system of

strapping, STILL worked the best, gave the most protection and peace of mind.

All of our full length bass cases (The Pro and the Ultra) come with a scroll

strap, a bottom neck (where it joins the body) strap, 2 straps across the

shoulders and two across the lower belly. This keeps the bass exactly in

the correct placement of how the case is designed to protect the bass. It

does not shift in flight jeopardizing the bass. Also, it is extremely

reliable and easy for the TSA or other airport customs people to close and re-attach if

needed.

All of our bass cases can either be used with our without a bass cover.

Cushions and positioning of the bass inside the case. Because we knew

what size the basses would fall within, we also knew where the key safeguards

needed to be. Concussion...that word again! On the very bottom of

the bass and case, all of our cases are specially designed to raise the bottom

of the bass up off of the endpin. If the bass sits on the endpin and at the very

bottom of the case, that endpin will act like a 'hammer' into

the bottom endpin block. Impacts here will knock the end pin block loose,

or crack the surrounding bottom bout ribs. Raising the bass upwards (just

enough so that the endpin tip is not sitting on or touching the bottom of the

case) , will spread and disburse the weight more evenly so that there is less risk

or impact. While both the Pro and the Traveler, use a raised

platform molded into the case, the Ultra uses specially molded cushions that

serve as the same purpose. All of our cases guard against bottom impact

(the most common) damage.

Composite materials make strong bass cases.

In the old days, (not very long ago) fiberglass cases were the 'cutting edge'

material, but with the new technological advancements available today, we went

all out! We use the following materials and processes in all of our cello

and bass cases: In the old days, (not very long ago) fiberglass cases were the 'cutting edge'

material, but with the new technological advancements available today, we went

all out! We use the following materials and processes in all of our cello

and bass cases:

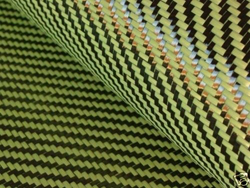

1) we use a special blend of carbon fiber, combined with Kevlar.

This material goes by other brand names: Spectra, Aramid, Vectra just to name a

few. The combination of the two 'composites' makes for super strong, firm

and at the same time impact resistant. Combining the strengths of these

two major materials is essential. In addition to combining the two aramids,

carbon fiber and kevlar, the process by which they are manufactured and joined

together is equally important. This also plays a key in achieving the

lightest, and strongest cases. In the old days (of hand made fiberglass)

makers would pour resin into the mold and hand roll the cloth out. While

it worked, we have learned over the years that the least amount of resin makes

the hardest, strongest parts! Less IS more! That's good news for a

stronger case and one much lighter in weight.

2) all of our composite cloth material is "pre-pregnated" with resin

when the cloth is 'milled' at the factory. There is a thin sheen of resin

that is immersed into the fabric. Once this process is done, these big

rolls of carbon/kevlar have to be refrigerated at our facility until the cloth

is cut into our case molds. Time is a big issue as the material now is

very heat sensitive and can literally start activating while we are setting up

the molds. Soon thereafter, the entire case mold part is wrapped and

bagged (sealed) so that during the next heat process stage, all or any excess

resin is vacuumed out of the mold and away from the part. (Why?)

Ever carry a can of paint from the paint store? It's heavy! Once the part gets activated

with the heat (autoclave) reducing every drop of excess resin will make it

stronger, and lighter. This stage of the manufacturing process is super labor

intensive and there are no short cuts to be made. sheen of resin

that is immersed into the fabric. Once this process is done, these big

rolls of carbon/kevlar have to be refrigerated at our facility until the cloth

is cut into our case molds. Time is a big issue as the material now is

very heat sensitive and can literally start activating while we are setting up

the molds. Soon thereafter, the entire case mold part is wrapped and

bagged (sealed) so that during the next heat process stage, all or any excess

resin is vacuumed out of the mold and away from the part. (Why?)

Ever carry a can of paint from the paint store? It's heavy! Once the part gets activated

with the heat (autoclave) reducing every drop of excess resin will make it

stronger, and lighter. This stage of the manufacturing process is super labor

intensive and there are no short cuts to be made.

3) Why White? This was simple. Yes, the black carbon weave

looks 'cool and stylish', but is actually way hotter for the instrument that you are trying

to protect. White reflects the heating sun rays. No exceptions are

made on this. All Tuff-Lites are white, inside and out.

4) Elastic bungee latches. What's up with that? At first, we

tried a regular metal latch on our bass cases. They looked so much

neater! In fact, using elastic bungees have several advantages: One,

when the metal latches on our old cases stood out, it was difficult to totally recess them or protect them from outside elements

the metal latches would eventually get broken somehow by the airlines.

Suitcases that get pushed onto or pulled across the latch would eventually loosen

the latch or the base of it. Often the composite at the base of the latch would have to be patched

for an expensive repair. The bungees too might get

snagged in the same manner that that metal latch will, but here the worst

scenario is that the bungee breaks and it is simple and quick to replace. No

need for costly or lengthy repairs to the exterior of the case. All cases

come with free replacement bungee cords and leather pulls as well. The TSA

loves our bungee latches as well. It is easier for them to open the case

and more importantly, easy for them to close the case back up. From our

experiences with orchestras and experienced touring musicians, they were also

concerned about easy access and easy (no brainer) kind of closing of the case.

We heard too many stories of how the basses would arrive at the destination city

only to find that the bass wasn't re-placed correctly by the TSA, or the bass

wasn't re-secured. Our latches and our interior strapping, easy to quickly

see and do. Here it wasn't the expert and attentive player we were thinking of,

but the customs or security people that just don't see a bass come through the

airport that often. much

neater! In fact, using elastic bungees have several advantages: One,

when the metal latches on our old cases stood out, it was difficult to totally recess them or protect them from outside elements

the metal latches would eventually get broken somehow by the airlines.

Suitcases that get pushed onto or pulled across the latch would eventually loosen

the latch or the base of it. Often the composite at the base of the latch would have to be patched

for an expensive repair. The bungees too might get

snagged in the same manner that that metal latch will, but here the worst

scenario is that the bungee breaks and it is simple and quick to replace. No

need for costly or lengthy repairs to the exterior of the case. All cases

come with free replacement bungee cords and leather pulls as well. The TSA

loves our bungee latches as well. It is easier for them to open the case

and more importantly, easy for them to close the case back up. From our

experiences with orchestras and experienced touring musicians, they were also

concerned about easy access and easy (no brainer) kind of closing of the case.

We heard too many stories of how the basses would arrive at the destination city

only to find that the bass wasn't re-placed correctly by the TSA, or the bass

wasn't re-secured. Our latches and our interior strapping, easy to quickly

see and do. Here it wasn't the expert and attentive player we were thinking of,

but the customs or security people that just don't see a bass come through the

airport that often.

There is a lot of thought, design and innovative work into all of our cases.

We want the lightest case possible, while still being strong, protective and

durable. The newest technologies developed help us achieve the most

innovative and functional cases.

|